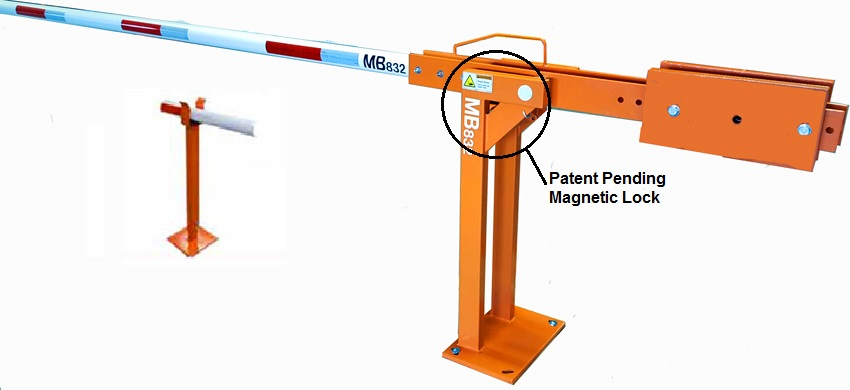

MB832-SA Semi-Automatic Barrier Arm Gate Operator

Semi- Automatic Magnetic Release Barrier Gate with Cradle or Tip Support

Top 4 Questions:

When do you need an arm support? A Boom Tip Support or Bolt Down Cradle is needed for arms over 18 ft long.

What length arm should I order for a 18 ft plus barrier gate that requires a fixed cradle?

When figuring your arm length, measure the “dirt to dirt ” distance from edge of asphalt of the roadway or back of curb(s) and add 1.5 ft or 18 inches to that dimension for the total arm length to order, but if using a tip support arm length isn’t critical.

How is the arm distance measured?

The arm length measurement starts even with the arm side of the base plate edge that runs parallel to and is closest to the street.

Can the barrier gate arm be locked?

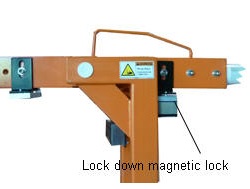

The arm can be locked in up or down position with a simple medium size padlock. The new system uses a magnetic lock fail-safe* controlled remotely to release barrier arm from its locked position to allow it to travel up or down automatically to its released positon. Also this unit can be ordered with an electrical mechanical lock fail secure** to release barrier arm from its locked position to allow it to travel up or down automatically to its released positon. Once the barrier gate is remotely actuated it is returned to the locked position by hand. The MB832SA can be additionally locked in the released position for added security. *Fail-safe arm unlocks during power failure ** Fail-secure arm stays locked during power failure.

Semi-Automatic Magnetic Release Barrier Gate Operation.

mb832 semi automatic barrier gate. The mag-lock holds barrier arm in the up position with 1200 lbs holding force.

Magnetic lock releases – barrier arm lowers. After power is cut to the mag-lock a torsion spring starts the arm moving to the down position.

Barrier arm in the closed Down Position in the down position additional mag-lock can be added to hold the arm down for added security.

Barrier in the magnetic locked down position. The mag-lock holds barrier arm in the down position with 1200 lbs holding force. When power to the mag-lock is cut the barrier arm will go up.

Magnetic lock releases – barrier arm goes up. After power is cut to the mag-lock counterweights start the arm moving to up position. Counterweights can be field adjusted to control speed

Barrier arm in the open up position. In the up position an additional mag-lock can be added to hold the arm up for added security

Why buy a Semi-automatic barrier gate versus an electric barrier gate?

This new type of barrier gate can be installed in a couple of hours anywhere and can be powered by a small solar panel with many remote control options saving substantial installation costs.

Typical Uses:

Emergency opening of roads, parking lots, industrial plants or any other facility that needs emergency one-way operation to egress traffic.Emergency closure of public roads during flooding, industrial plant fires, traffic control for guard shack use to stop vehicles.

Specifications:

- Round Aluminum powder coated arm 3″ O.D. ; 8 to 32 ft length pre-cut and balanced at the factory

- High quality DOT reflective tape included

- Frame is heavy steel construction- 5/8″ Base Plates and thick tubular construction using structural hot-rolled steel.

- Plastic signage available (stop, do not enter, etc)

- Three sizes of steel counterbalance plates for balancing arms up to 32 ft in length

- Arm can be locked by padlock in the up or down positions for added security and safety.

- All parts are powder coated orange for durability.

- Pivot assembly is made of durable maintenance free plastic bushings and bolt assembly

- Tip support cradle (MB cradle) is suggested for arm lengths over 18 ft

- Orange powder coating standard on all other components

- Self-supporting round Aluminum barrier arms

- Stainless Steel and Galvanized Hardware for long life.

- MB Drop-down Tip Support for areas where the MB cradle cannot be used.

- Barrier arm catcher/ Cradle is optional for shorter arms for added support

Dimensions:

Base plate: 16″ X 10.5″; height of arm above pavement 35″; overall height 37″; width of frame 10″ X 10″; base- 4 holes 5/8″ dia.; length of counterweight arm from pivot 32.5″ Maximum.

Shipping Wt. 182 to 502lbs depending on arm length.